Free for 3 users or 14 days. No credit card required

澳洲幸运10开奖直播结果-正规官方网址

Goal-Setting and Tracking

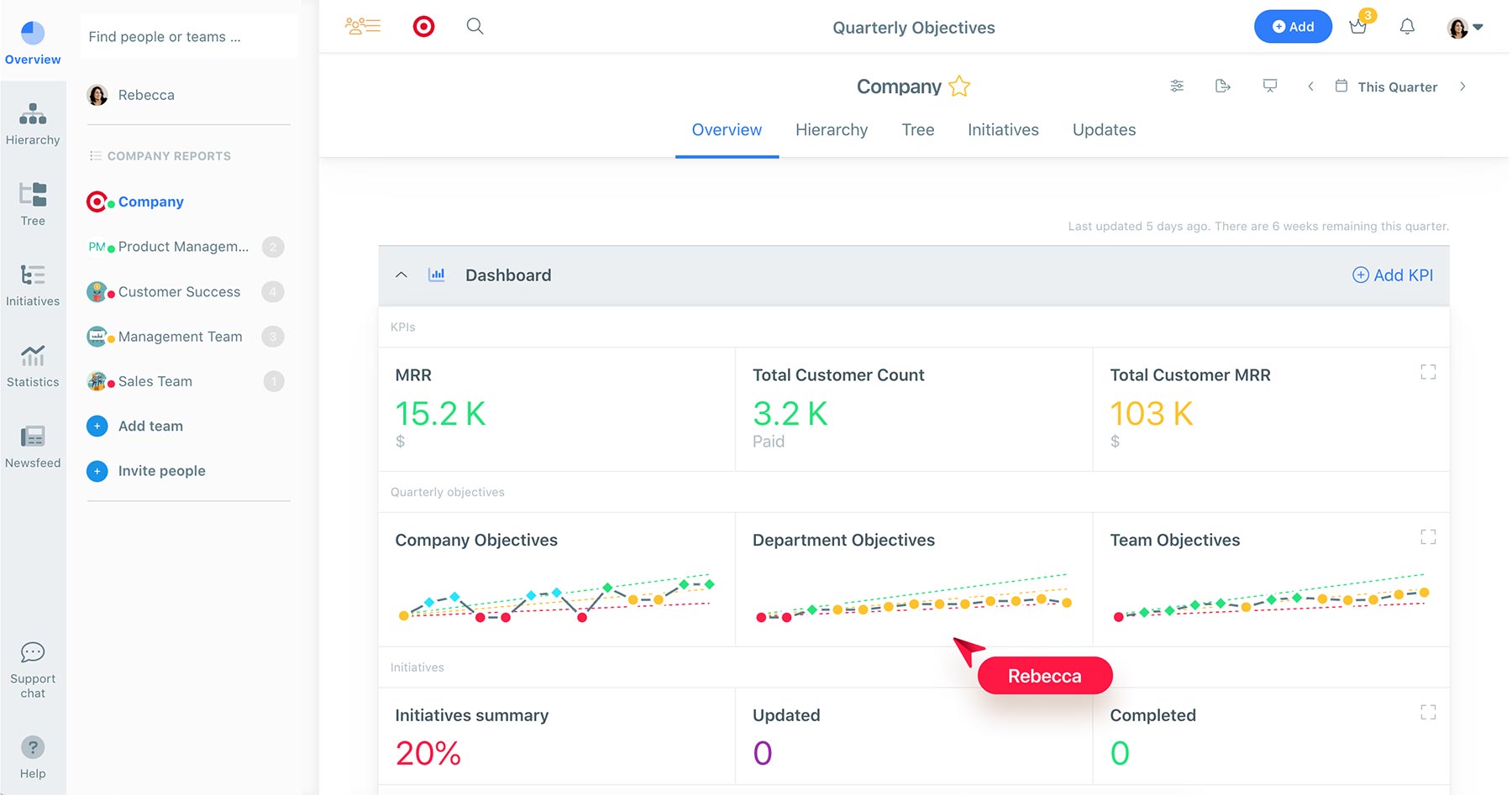

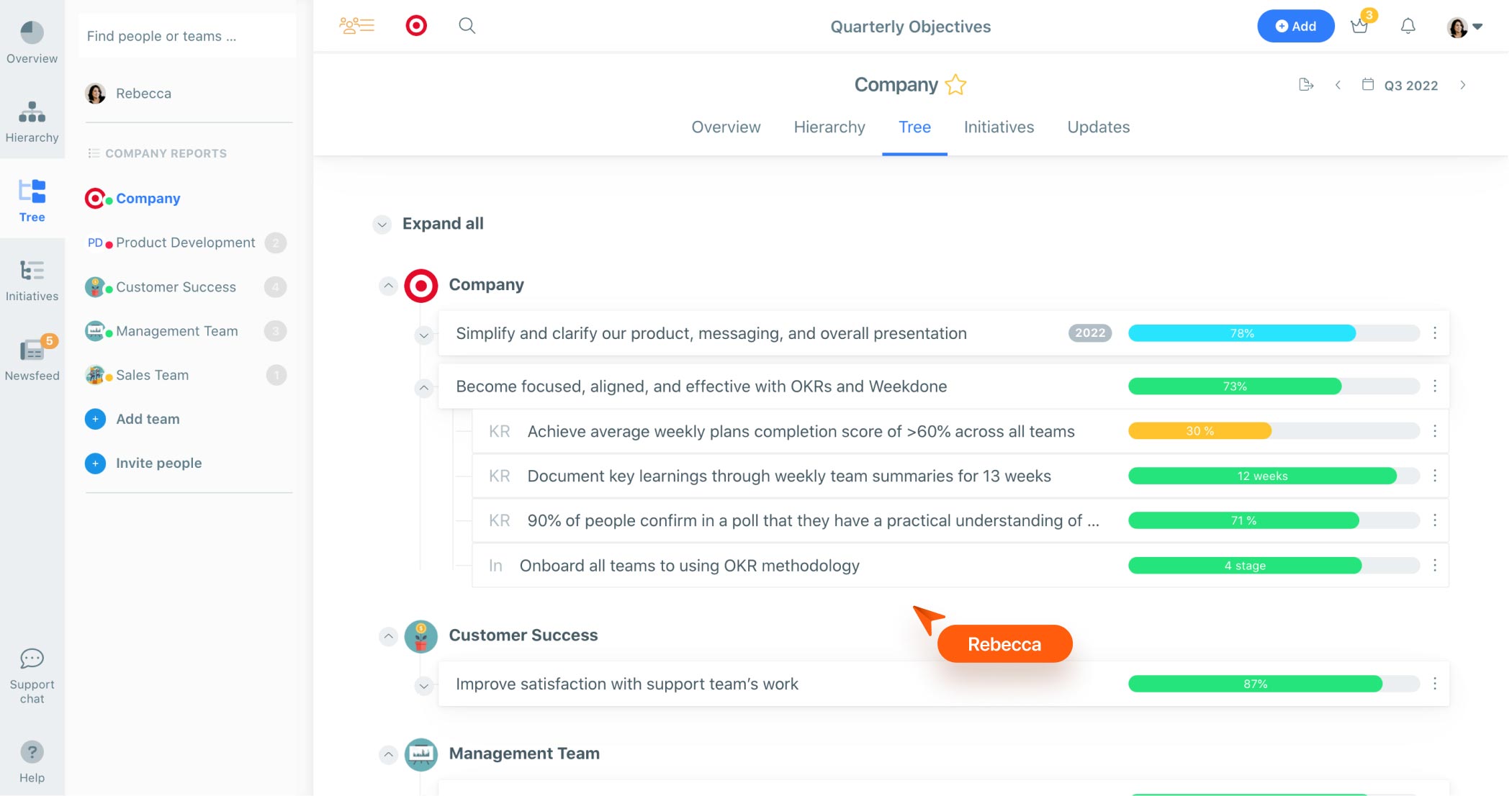

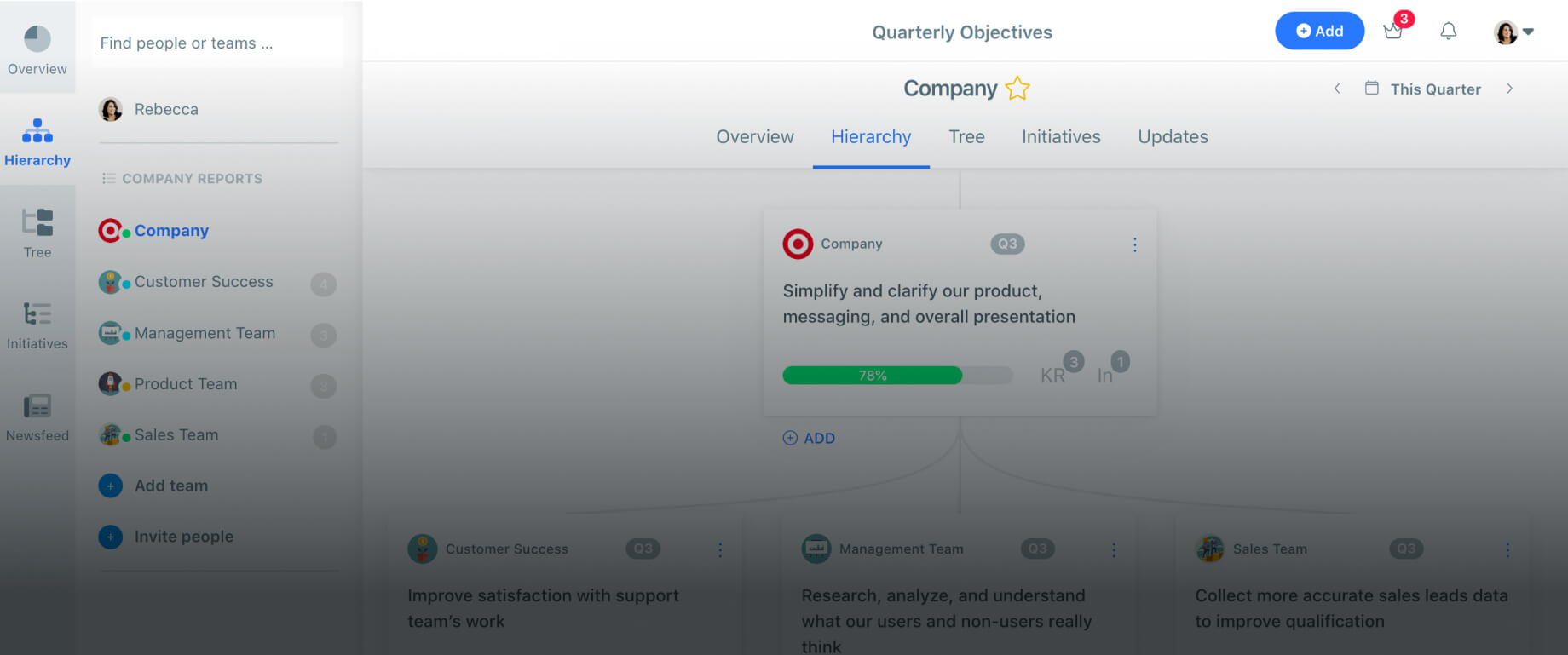

* Objectives and Key Results

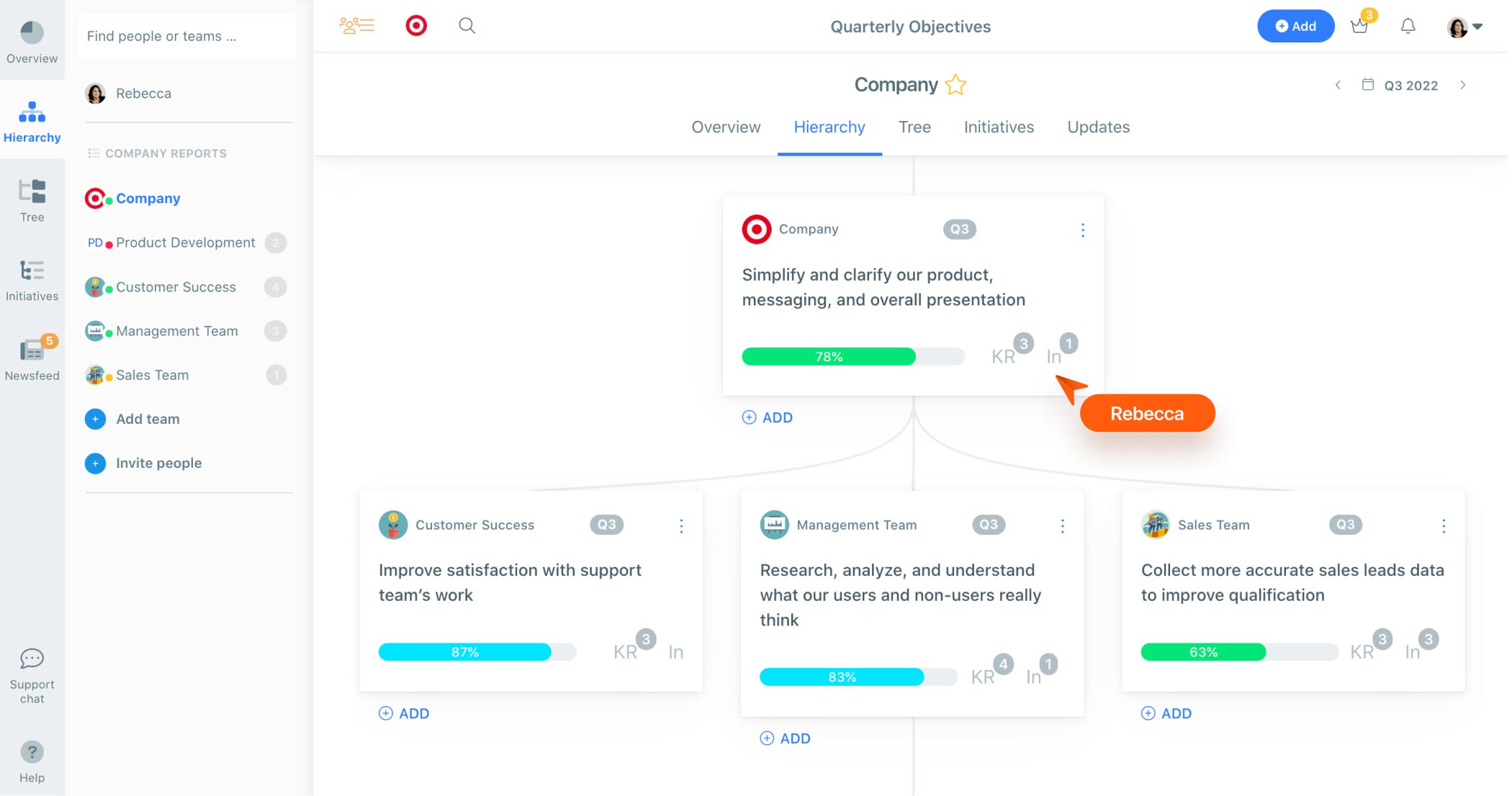

* Visual OKR Hierarchy Tree

* Align and Link OKRs

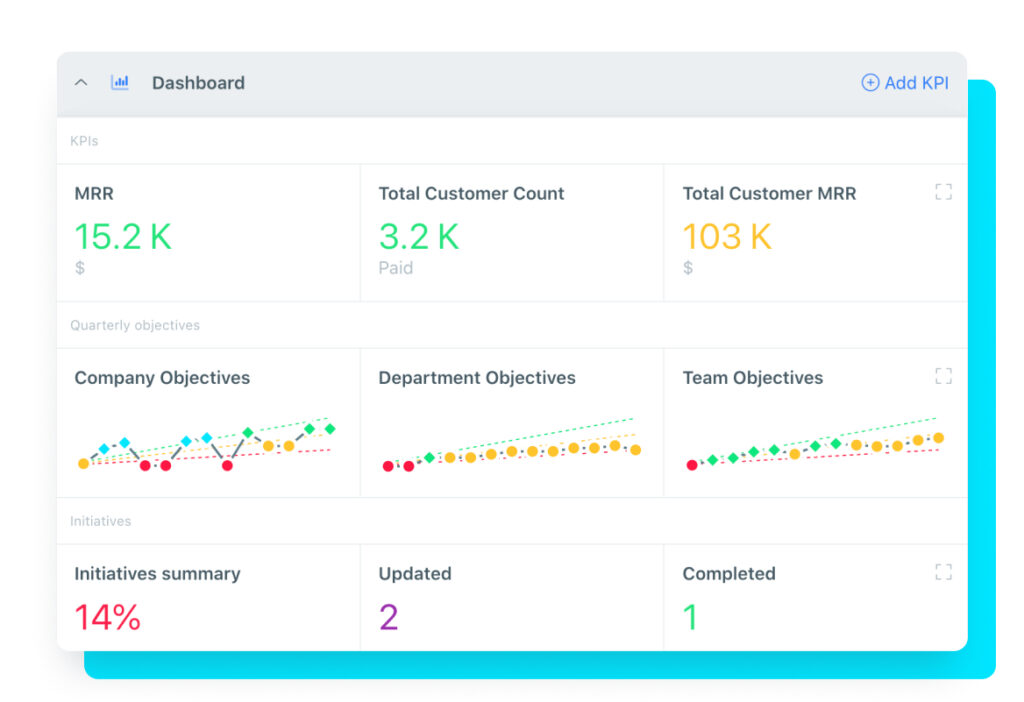

* KPIs and Metrics

* Projects and Initiatives

Weekly Planning and Reporting

* Automated Weekly Status Reports

* Weekly Planning

* Custom Templates

* Prioritization

* Custom Integrations

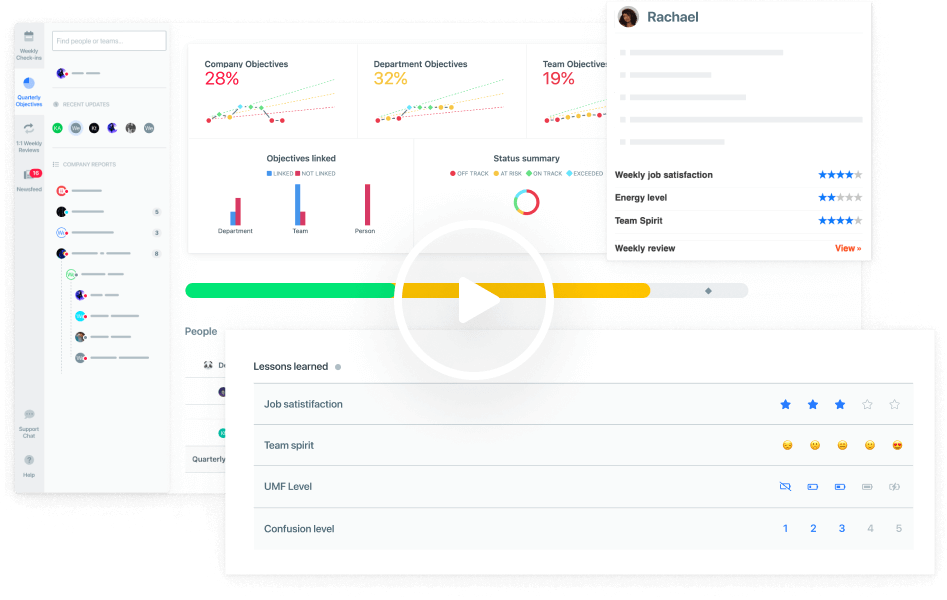

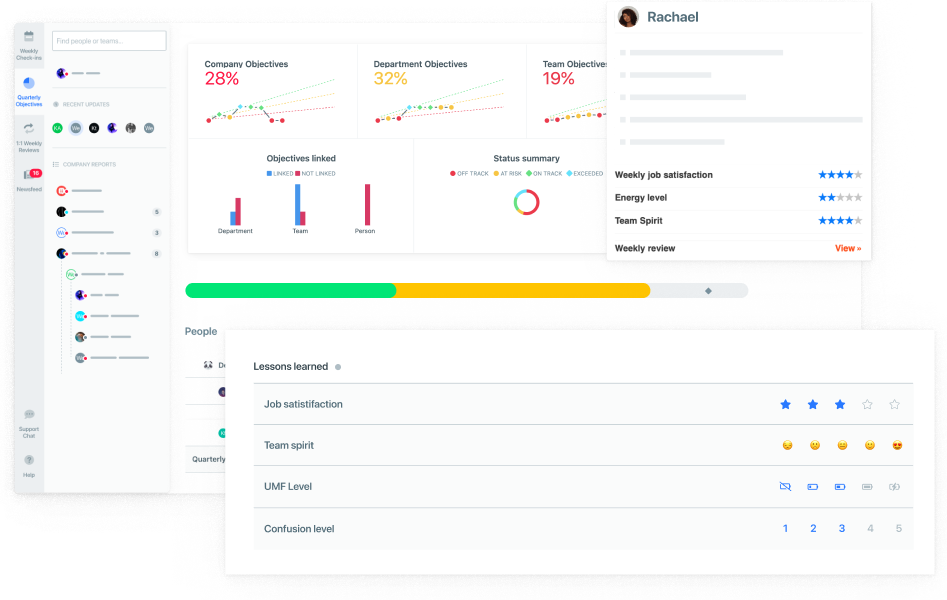

Pulse Surveys and Check-ins

* 5-star Ratings

* Pulse Surveys & Check-ins

* Feedback and Recognition

* Measure Employee Engagement

1:1s and Team Announcements

* Private 1:1 conversations

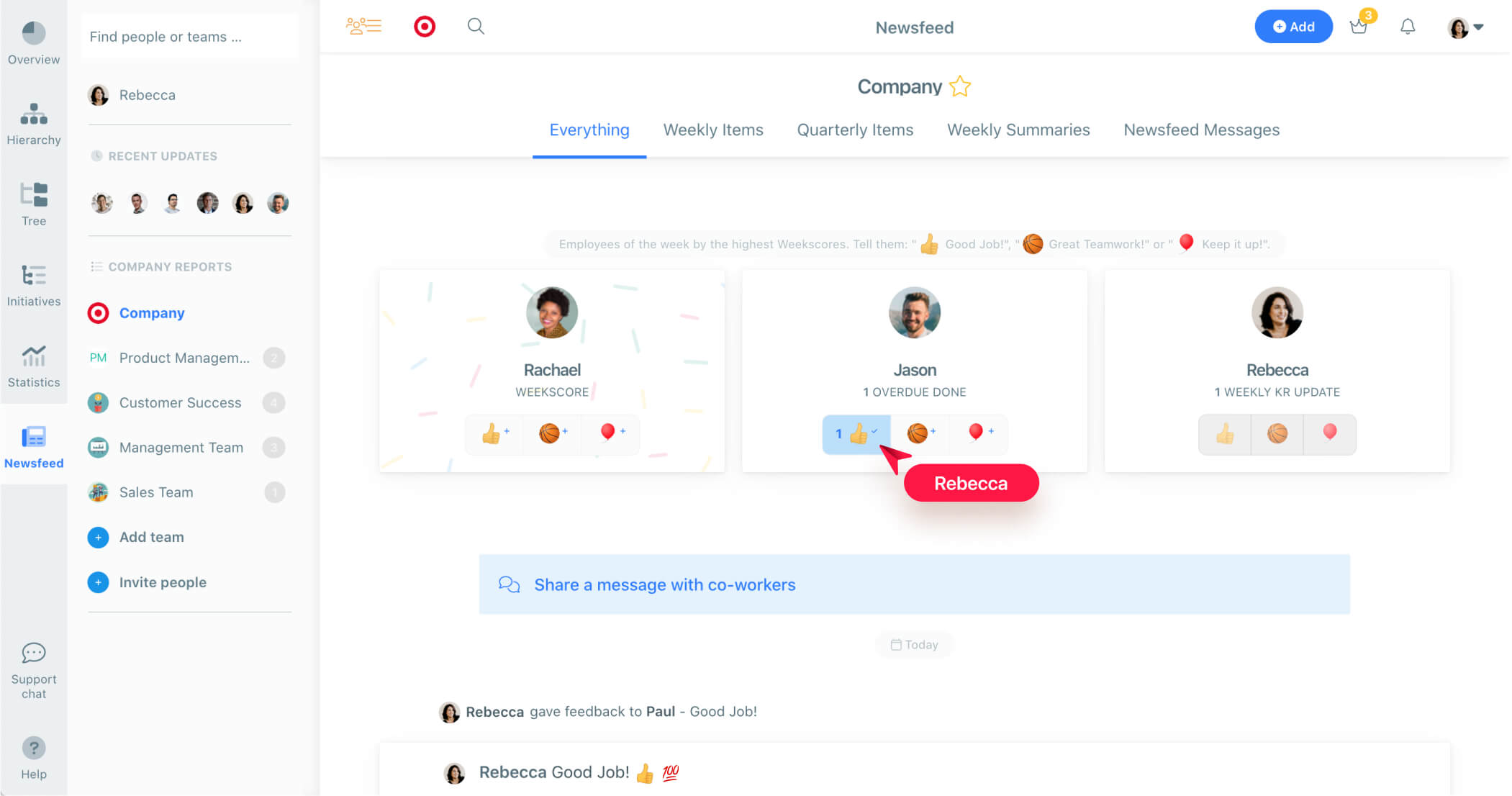

* Kudos and Upvotes

* Meeting Agendas

* Calendar View

* Social Newsfeed

Add, update and edit OKRs inline. See and export progress reports.

Visualize OKR hierarchy across the company and all levels.

Understand OKR progress throughout the company at a glance.

See progress updates, announcements and give out awards all in one place.

The Flow to Success

- Quarterly

- Weekly

- Daily

- As needed

-

1

Set quarterly goals

-

2

Plan your week

-

3

Share progress

-

4

Provide feedback

-

5

Get regular reports

Let’s Tackle Your Team’s Problems

Why Every Leader Needs Weekdone

Weekdone OKR and team management software

Free for 1-3 users or 14 days • Full features • No credit card required